This story first appeared at Marijuana Business Daily.

Whether operating indoors, outdoors or in greenhouses, cannabis cultivators have developed a reputation for not being as green as the plants they grow.

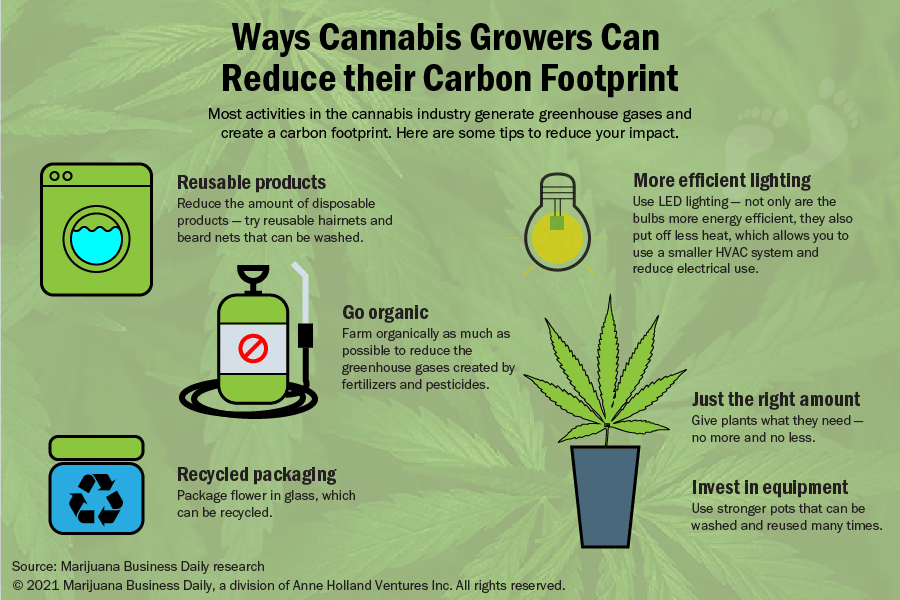

From pesticides to energy use, there are a myriad of ways growers can cut back on their carbon footprint. Some require a little investment, while others are relatively inexpensive.

Regardless, consumers are increasingly demanding products that are produced with minimal impact on the planet, and cannabis cultivators are taking note.

“Fundamentally, one of the really cool things about agriculture and cannabis agriculture is they have aligned goals, not opposed goals,” said Graham Farrar, president and chief cannabis officer at California-based Glass House Group.

“Running a good cannabis operation is by definition a sustainable one. Sustainable agriculture is also good business.”

Marijuana growers can reduce their carbon footprints by:

- Reducing the amount of disposable products they use — try reusable hairnets and beard nets that can be washed.

- Using stronger pots that can be washed and reused many times.

- Using LED lighting — not only are the bulbs more energy efficient, they put off less heat, which allows you to use a smaller HVAC system and reduce electrical use.

- Giving plants what they need — including fertilizer and water — no more and no less, which can be captured, sterilized and reintroduced.

- Replacing chemical pesticides with sustainable biocontrols wherever possible.

Waste is key

“The low-hanging fruit for any cultivator is waste,” said Ben Gelt, board chair and co-founder of the Cannabis Certification Council, a nonprofit focused on consumer and industry education.

“There’s a lot of opportunity to reuse, compost and recycle.”

Cannabis cultivation consultant Av Singh of Wolfville, Nova Scotia-based Flemming & Singh Cannabis Inc. said one way to reduce waste is to limit the use of disposable products such as hairnets and other garments worn in cultivation facilities.

He recommends wearing non-slip footwear that can be sanitized rather than putting on new shoe covers every time an employee enters a grow room.

Another waste-reducing measure is to use stronger pots that can be washed between harvests.

“Hard plastic can go through a commercial dishwasher or hand wash many times before it ever ends up in a landfill,” Singh said.

Perhaps the area that generates the greatest amount of waste is packaging, but stringent regulations make it difficult to reduce waste while staying in compliance.

A standard 3.5-gram unit of dried cannabis comes packaged in more than 70 grams of plastic, according to a Policy Lab report from McGill University in Montreal, Quebec.

“Packaging really makes the products more expensive and the industry less eco-friendly,” said Farrar, who suggests cultivators package their products in glass that can be recycled.

There also are packaging options that use ocean-harvested plastics or those derived from hemp plants.

Reducing electrical consumption

Perhaps the biggest contributor to the cannabis industry’s environmental footprint is energy.

Indoor cannabis production accounts for an estimated 1.3% of Colorado’s total greenhouse gas emissions, according to a recent study by Colorado State University published in Nature Sustainability.

The indoor lighting and cooling systems required to grow marijuana indoors have a significant impact on climate.

“Making decisions that reduce your utilization of electricity is a fantastic way to reduce your carbon footprint,” said David Kessler, chief science officer of Burlington, Massachusetts-based Agrify, which makes hardware and software for indoor cannabis cultivators.

Among the steps cultivators can take to reduce energy consumption is switching to LED (light-emitting diode) lighting.

LED light systems cost more than HID (high-intensity discharge) or high-pressure sodium lighting, but the return on investment from energy savings may offset those initial installation costs.

Not only is LED lighting more efficient than traditional HID lighting, it produces less heat, which means a cultivator can operate a smaller HVAC system or a chilled water system that uses less electricity, Kessler said.

A chilled water system also gives growers the option of using a natural gas as their fuel source rather than electricity.

“If you do a cost analysis and look at the impact on the environment, you may prefer to use natural gas over electricity,” Kessler said.

Growing organic hemp

Unlike marijuana, hemp crops can be certified as organic under the U.S. Department of Agriculture National Organic Program.

A crop can only be certified if the land has been managed without the use of synthetic fertilizers and pesticides for 36 months before the crop is harvested.

Ryan Cross, operations manager for the Gloucester, Virginia-based organic hemp producer River Organics, said soil management plays a key role in reducing the company’s carbon footprint.

Crop rotation, organic fertilizers and minimal tilling are the core principals of River Organics’ crop production plan and help the company mitigate how much carbon it is producing.

It spaces its rows 8 feet apart and plants a cover crop between them to reduce soil erosion and suppress weeds.

“In the off season when we’re not growing hemp, we have a legume or a winter rye,” Cross said.

Cross said that growing hemp plants organically speeds up the drying process because plants that are grown organically don’t retain as much water as those that are grown conventionally because of how quickly they absorb fertilizer.

That decreases the amount of time harvested plants must be stored, which helps to lessen the company’s carbon footprint.

An added benefit, Cross said, is that growing organic improves the production of flavonoids and terpenes by about 12%.

Eliminating pesticides is another sustainable practice cultivators can employ whether they’re growing marijuana or hemp.

Glass House Farms, for example, has eliminated the use of pesticides that are harmful to the planet, employees or customers by spending about $30,000 a month on Integrated Pest Management (IPM), a cost Farrar said will come down as more people implement the practice.

“It’s the high-tech version of ladybugs — we use about 40 different bugs,” he said. “Insectaries are getting bigger. As you get bigger, your cost comes down.”